Digital control of pump and valve technology

Whether centrifugal pump, solenoid valve or complex control system – in fluid technology, every component counts. And even more so their reliable service. Customers expect maximum system availability, standard-compliant maintenance and fast response times.

With SIMPL, you can digitize your service organization from the ground up: Scheduling, test and maintenance documentation, spare parts management and customer communication – efficient, standard-compliant and perfectly tailored to pump, valve and fluid technology manufacturers.

30

-40

60

Service is becoming more complex - and customers more demanding

Pump and valve manufacturers are under double pressure today: on the one hand, customers expect short response times, transparent documentation and reliable maintenance. On the other hand, the mix of manual processes, scattered information and a lack of service overview often slows things down internally.

Unnecessary queries, delays and loss of sales in after-sales arise, particularly with products that require explanation and have long lead times – because important data is not available digitally or customers are only involved to a limited extent. If there is no structured service organization, not only does efficiency suffer – but also long-term customer loyalty.

Structured service - even for complex components

With SIMPL, you digitize your entire service organization – from scheduling to spare parts documentation. You manage all customer systems, test logs and maintenance histories centrally, ensuring clear processes, fewer queries and significantly better responsiveness in customer service.

SIMPL also offers the necessary flexibility for products that require explanation, such as pumps, valves or control components: individual maintenance plans, product-related checklists and digital service reports can be easily mapped – without additional effort for your team.

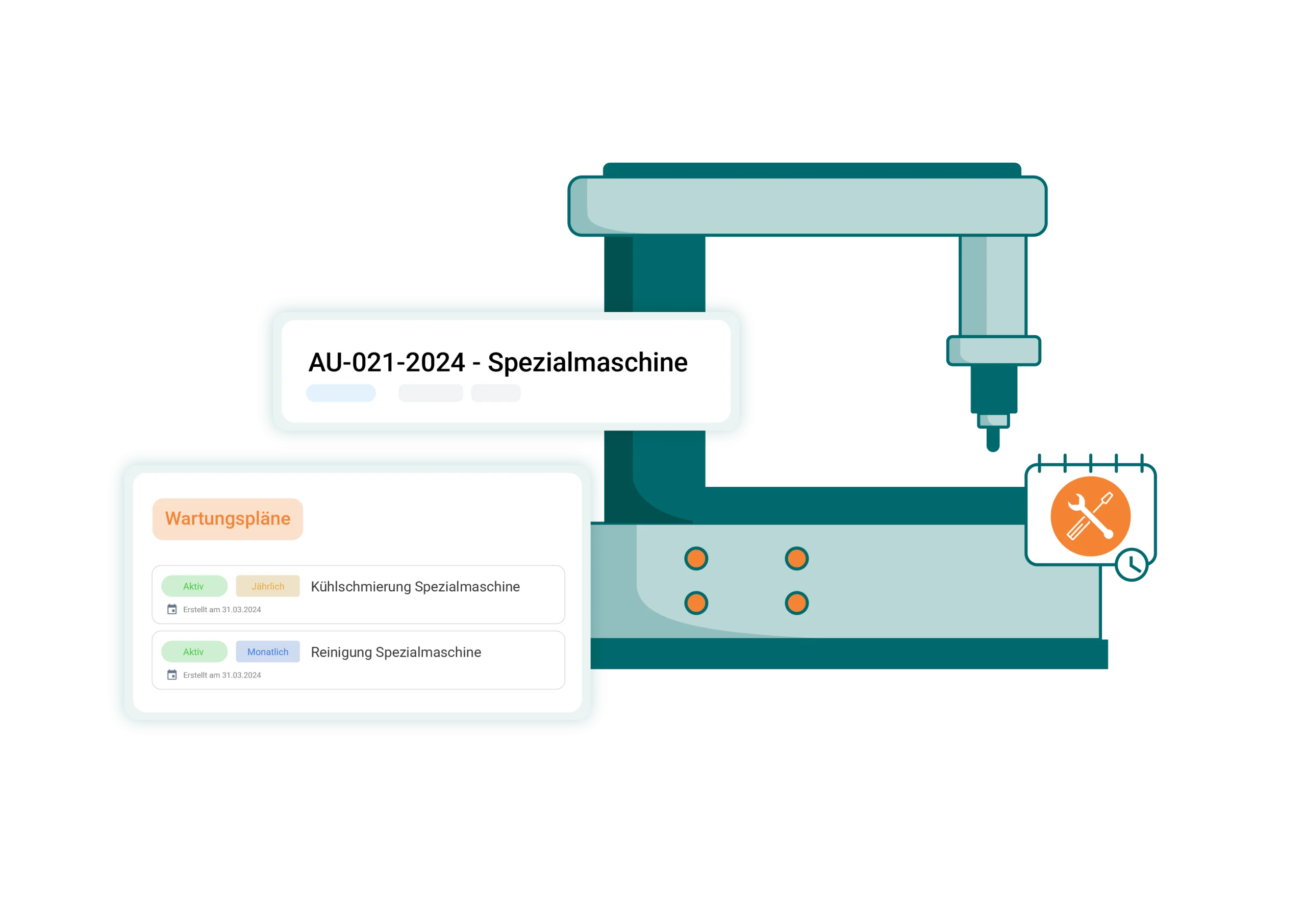

Digital service files for every product

Whether a standard appliance or a special version – SIMPL bundles all relevant information for each component: Maintenance history, test logs, installation and operating instructions, service reports and spare parts lists.

This saves time in the event of queries, facilitates internal coordination and creates transparency throughout the entire product life cycle.

All pump, valve or assembly data in one place

All maintenance, documents & service cases - directly visible on the asset

Create individual maintenance and inspection intervals for each product – tailored to operating conditions, standards or customer agreements. Service technicians work with predefined checklists and record all measures in a mobile and standard-compliant manner – including signature and photo documentation.

Component-specific planning, execution and documentation

This is the easy way to generate QR codes for your machines & systems

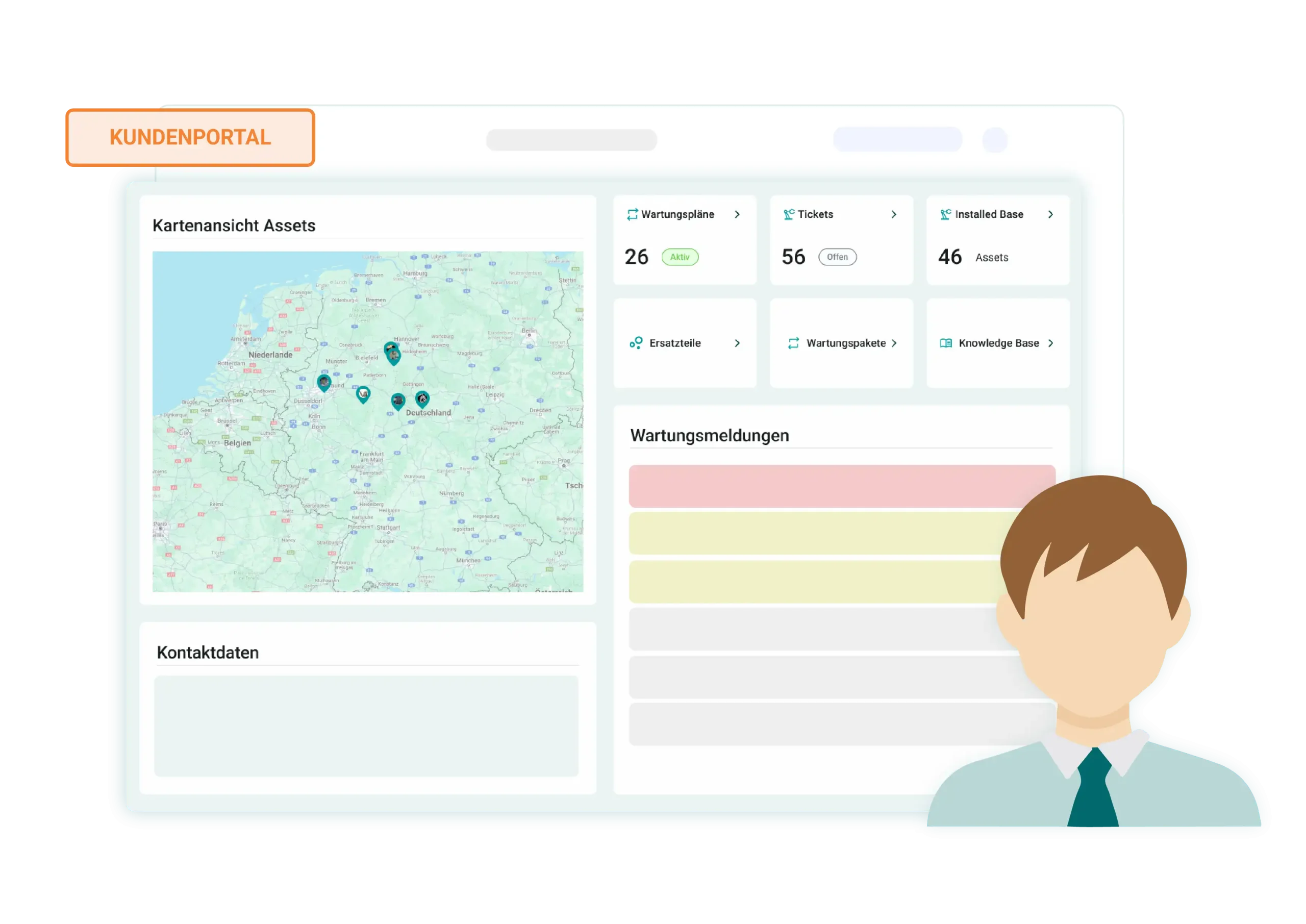

Provide your customers with a portal where they can access all information about their installed products: Maintenance histories, planned service calls, logs and spare parts. This takes the pressure off your team – and noticeably increases service quality.

Provide service reports, maintenance plans and spare parts digitally

From product to service – structure your after-sales processes with SIMPL

Digitize maintenance, service reports and customer communication relating to pumps and valves – centrally, efficiently and in compliance with standards.

Individual support from real contacts

We accompany you personally – with support that understands your industry. No call center, no script – just fast, direct help from people who really know SIMPL.

Intuitively developed for use on site

SIMPL also works where speed is of the essence: mobile, offline-capable, without long training periods. Your technicians will get to grips with it straight away – whether using a tablet or smartphone.

Made & hosted in Germany

Our servers are located exclusively in Germany, are ISO 27001-certified and GDPR-compliant. Do your customers demand confidentiality? We provide it as standard.