Smart digitalization of service processes for packaging and food machinery

Whether it’s a flow-wrapping machine, filling line or labeler – every detail counts in the packaging and food machinery sector. Your customers expect smooth commissioning, predictable maintenance and rapid availability of service teams and spare parts.

With SIMPL, you can bring structure to your service organization: from resource planning and mobile documentation to the customer portal – everything is digital, efficient and precisely tailored to the requirements of the packaging and food machinery industry.

-40

60

25

Offer a structured service - instead of just "delivering along"

With SIMPL, you as a machine manufacturer can set up a professional, scalable service organization – without additional effort for your team. You plan service assignments in a structured manner, document services on site and provide maintenance plans, reports and spare parts data digitally.

Especially with packaging and food processing machines, where reliability and hygiene are key, you create trust, efficiency – and new sales potential in after-sales. SIMPL not only helps you to look after your machines better, but also to position your service as real added value.

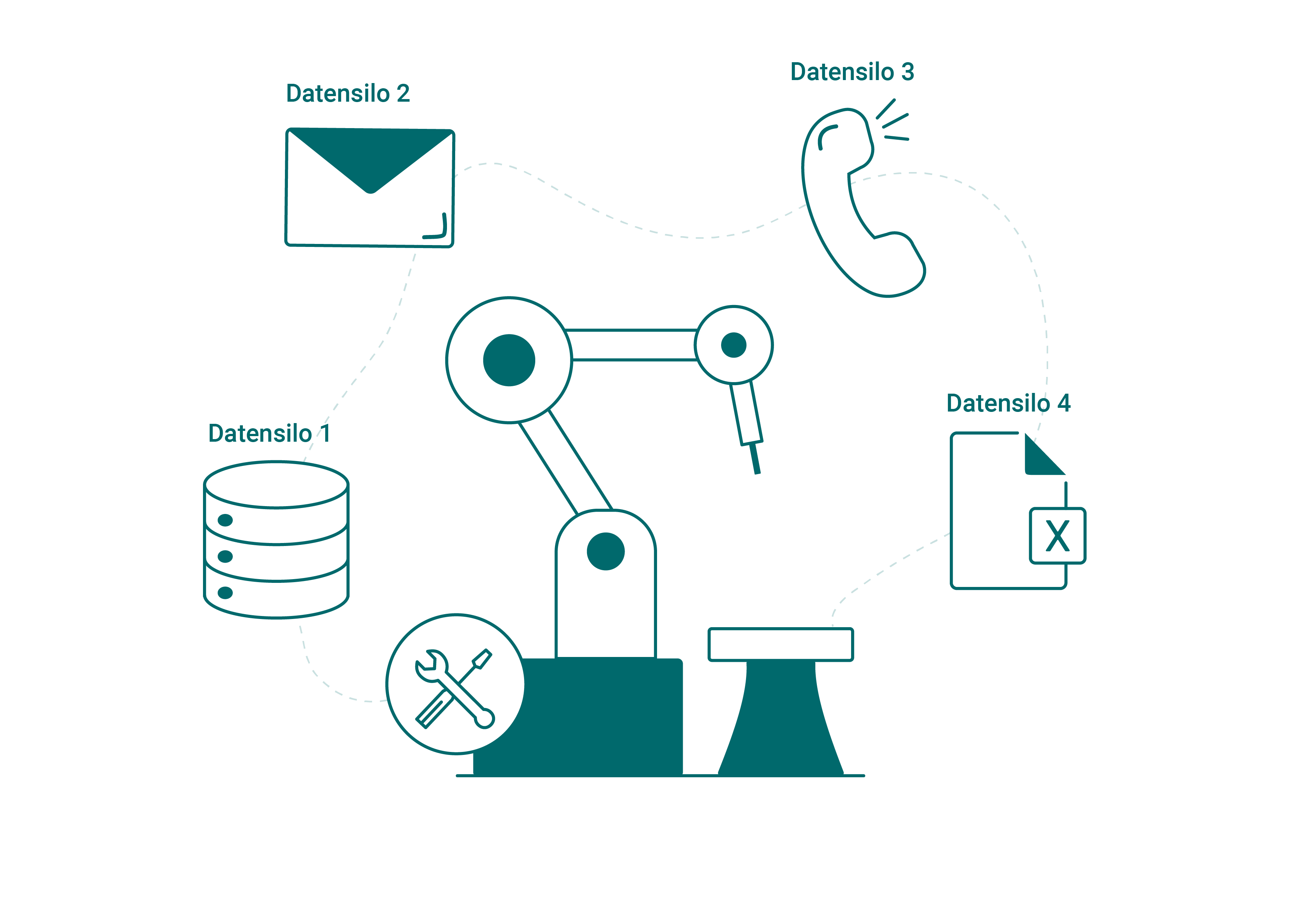

Mapping service professionally - instead of reacting ad hoc

With SIMPL, you create the digital basis for a structured and scalable service for your machines – from planning and execution to documentation. You organize maintenance, commissioning and format changes centrally, find out immediately what is happening at the customer’s site and make reports and maintenance histories available digitally at any time.

In this way, you reduce internal coordination effort, reliably meet industry-specific requirements (e.g. IFS, BRC) and position your service as real added value – not as a stopgap solution.

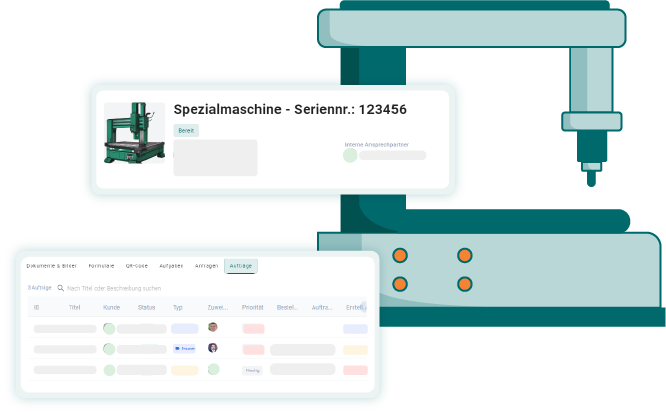

Digital resource planning & format change management

With SIMPL, you can plan service calls for your systems with foresight – including maintenance, repairs or format changes. Scheduling takes into account machine locations, technician availability and maintenance intervals. Changes to products or packaging formats can be easily integrated into the planning.

Plan service assignments with foresight and adapt them flexibly

-

Create QR codes directly in SIMPL with a click

-

PDF or label export for immediate use

-

Each system receives a unique, scannable ID

Hygiene-related documentation & mobile service reports

Service technicians record their work directly at the machine: including cleaning measures, seal changes, format changes or hygiene approvals. The reports are standardized, complete and can be documented in accordance with IFS and BRC – without paper chaos.

Audit-proof service logs – digital and standard-compliant

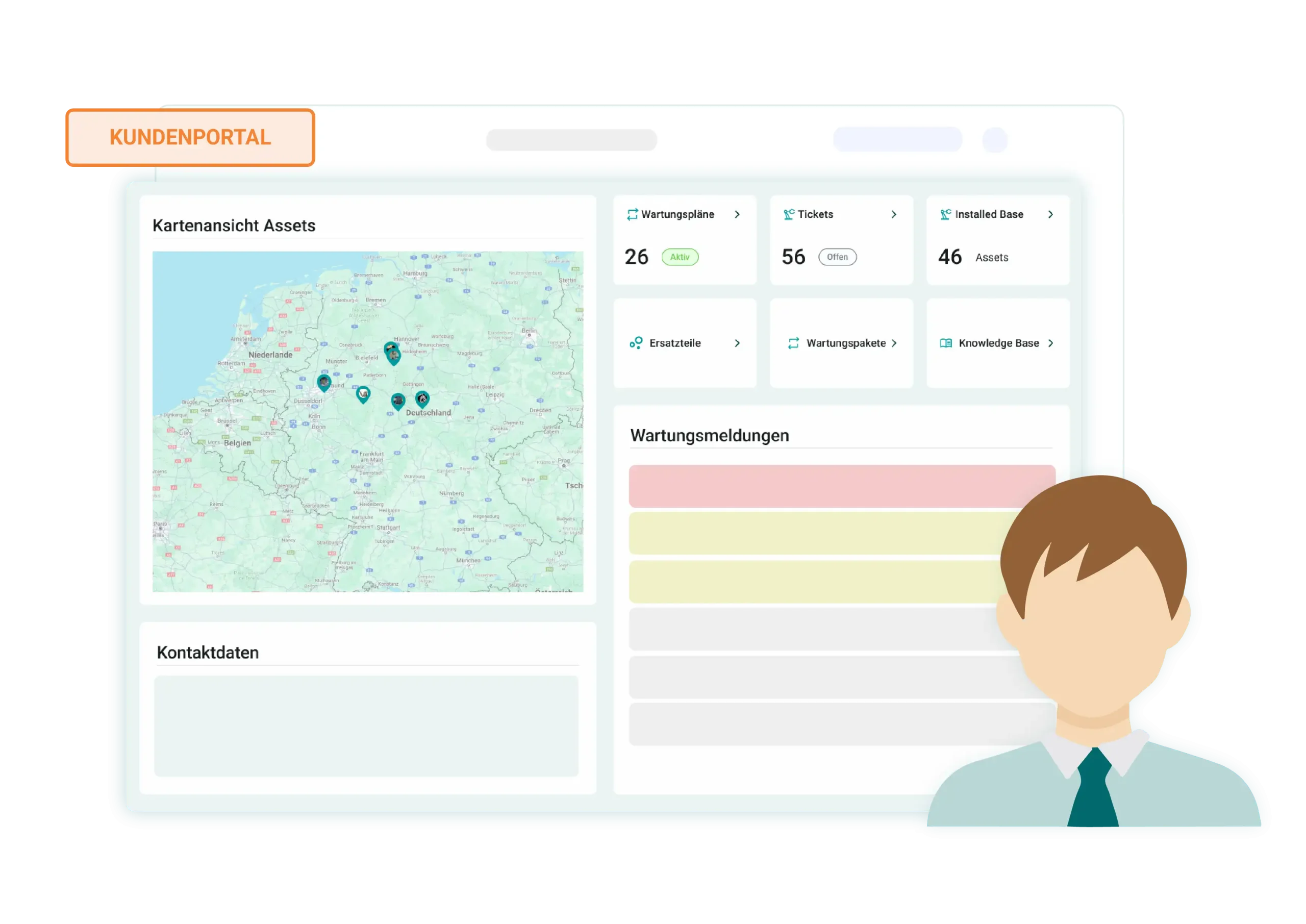

Customer portal for machine operators

Provide your customers with a portal where they can access all relevant information about the system – from services performed to the next maintenance. This saves queries, speeds up approvals and makes your service much more attractive for operators.

Provide service reports, maintenance plans and spare parts data

Turn your service into a real selling point

With SIMPL, you digitize your after-sales for packaging and food machinery – efficiently, in compliance with standards and customer-oriented.

Individual support from real contacts

We accompany you personally – with support that understands your industry. No call center, no script – just fast, direct help from people who really know SIMPL.

Intuitively developed for use on site

SIMPL also works where speed is of the essence: mobile, offline-capable, without long training periods. Your technicians will get to grips with it straight away – whether using a tablet or smartphone.

Made & hosted in Germany

Our servers are located exclusively in Germany, are ISO 27001-certified and GDPR-compliant. Do your customers demand confidentiality? We provide it as standard.