Organize maintenance in metal & plastics processing digitally

Whether injection molding machine, CNC machining center or sheet metal press – every minute of machine running time counts in metal and plastics processing. At the same time, the requirements for transparency, documentation and preventive maintenance are increasing. However, in many places, maintenance is still carried out in analog form – with slips of paper, Excel or confusing processes.

With SIMPL, you can digitize your maintenance from incidents to preventive maintenance – complete, mobile and traceable. For fewer downtimes, clearer processes and production that can rely on technology.

26

100.000

20

High cycle rate - but outdated processes in maintenance?

In metal and plastics processing, time equals turnover: every unplanned malfunction or delayed maintenance can delay entire production lines. However, many companies lack a structured, consistent maintenance organization – instead, spontaneous reactions, paper documentation and on-call coordination dominate.

This leads to unnecessary downtime, overworked teams and a lack of transparency regarding causes and repeat errors. And: without digital processes, downtime costs remain high – and potential for improvement remains untapped.

Structuring maintenance digitally - for stable processes and less downtime

With SIMPL, you digitize your maintenance processes from incidents to preventive maintenance – structured, traceable and available on mobile devices. You plan assignments in a targeted manner, reduce spontaneous emergencies and document measures directly on site – including spare parts, root cause analysis and downtimes.

All data flows into a central overview: you recognize patterns, repeat errors and workload in real time – and can avoid downtimes in a targeted manner. This takes the pressure off your team, ensures system availability and creates a maintenance system that can keep up with the pace of your production.

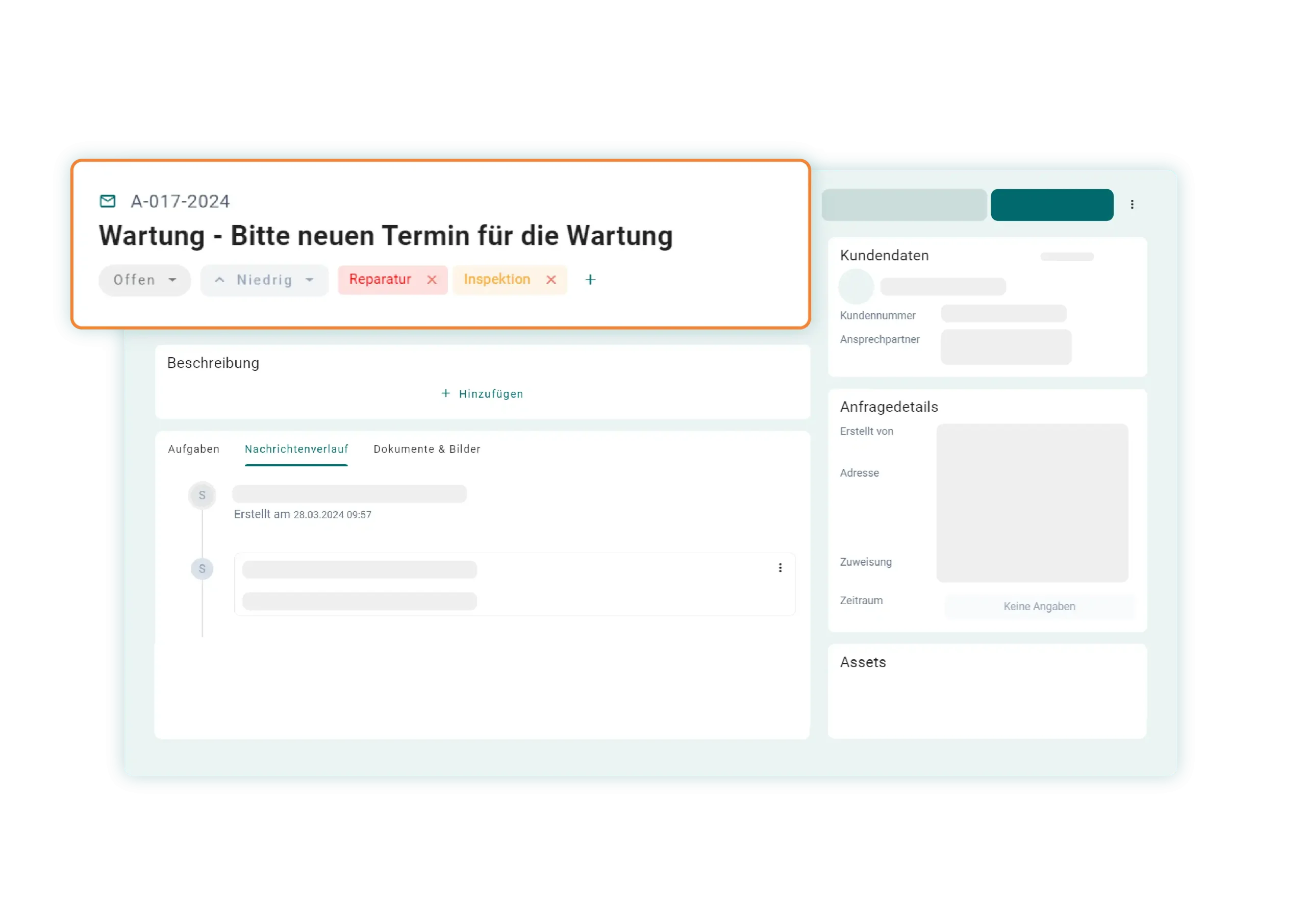

Fault management & mobile deployment control

With SIMPL, you can record faults digitally – directly by operators or automatically via interfaces. Maintenance prioritizes assignments, allocates them and responds without losing time. This creates transparent processes instead of ad hoc chaos – even in shift operation.

Shorten response times – avoid spontaneous emergencies

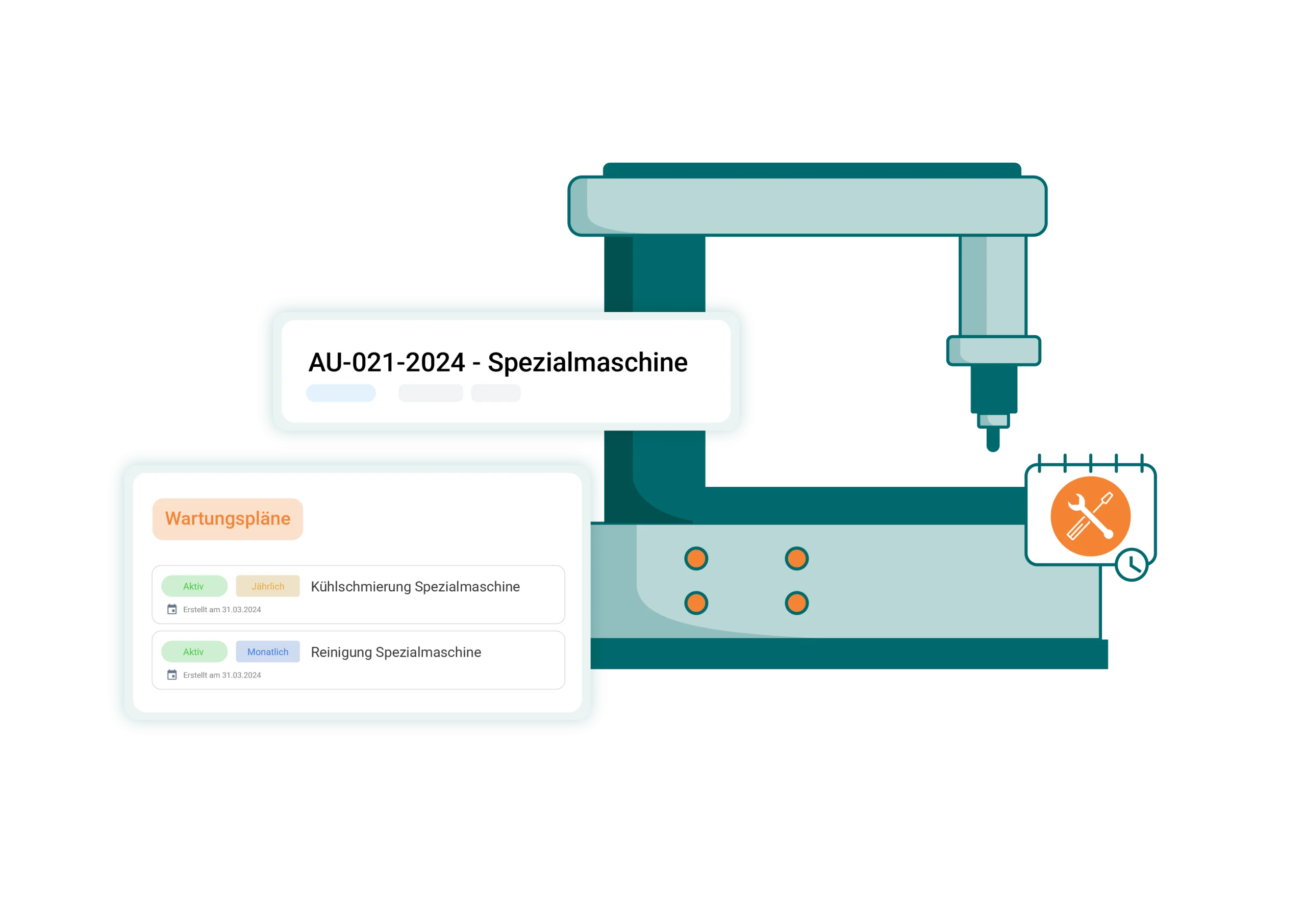

Preventive maintenance & repeat fault detection

Whether milling machine or injection moulding system – with SIMPL you plan maintenance intervals, define checklists and detect repeat errors through structured feedback. Causes, measures and parts used are documented – for well-founded improvements.

Plan maintenance, analyze causes and avoid errors in the long term

Evaluation & Keeping an eye on capacity utilization

With SIMPL, you can analyze downtimes, resource distribution, material consumption and system availability at the touch of a button. You can see where you are losing too much time – and where your maintenance can become more efficient.

Make maintenance measurable – recognize bottlenecks early on

Less downtime. More availability. Better overview.

With SIMPL, you can manage your maintenance digitally – efficiently, traceably and without paper chaos.

Individual support from real contacts

We accompany you personally – with support that understands your industry. No call center, no script – just fast, direct help from people who really know SIMPL.

Intuitively developed for use on site

SIMPL also works where speed is of the essence: mobile, offline-capable, without long training periods. Your technicians will get to grips with it straight away – whether using a tablet or smartphone.

Made & hosted in Germany

Our servers are located exclusively in Germany, are ISO 27001-certified and GDPR-compliant. Do your customers demand confidentiality? We provide it as standard.