Service as a competitive advantage: digital support for machine tools

As a manufacturer of machine tools, you know: Service has long been a decisive competitive advantage. Customers expect maximum availability, fast response times and smooth after-sales processes. With SIMPL, you digitize maintenance plans, service calls and customer communication – efficiently, transparently and mobile. This allows you to sustainably increase customer satisfaction and your service turnover.

25

4

-20

Growing service requirements meet inefficient processes

Today’s customers expect more than just a reliable machine – they demand fast support, predictable maintenance and transparent services. However, many machine tool manufacturers are still struggling with paper-based processes, scattered information and long response times. The result: dissatisfied customers, high internal costs and missed sales potential in after-sales service. The more complex your machines and systems, the more important a consistent, digitally supported service process becomes – both internally and externally.

Your service - digital, efficient and customer-oriented

With SIMPL, you can digitize your entire service and after-sales processes for machine tools – from scheduling and mobile service recording to transparent customer communication. You control all maintenance and service calls centrally, reduce downtimes and provide your customers with access to relevant information such as machine histories or maintenance plans at all times.

➔ Faster response times, greater customer satisfaction and new sales potential in after-sales.

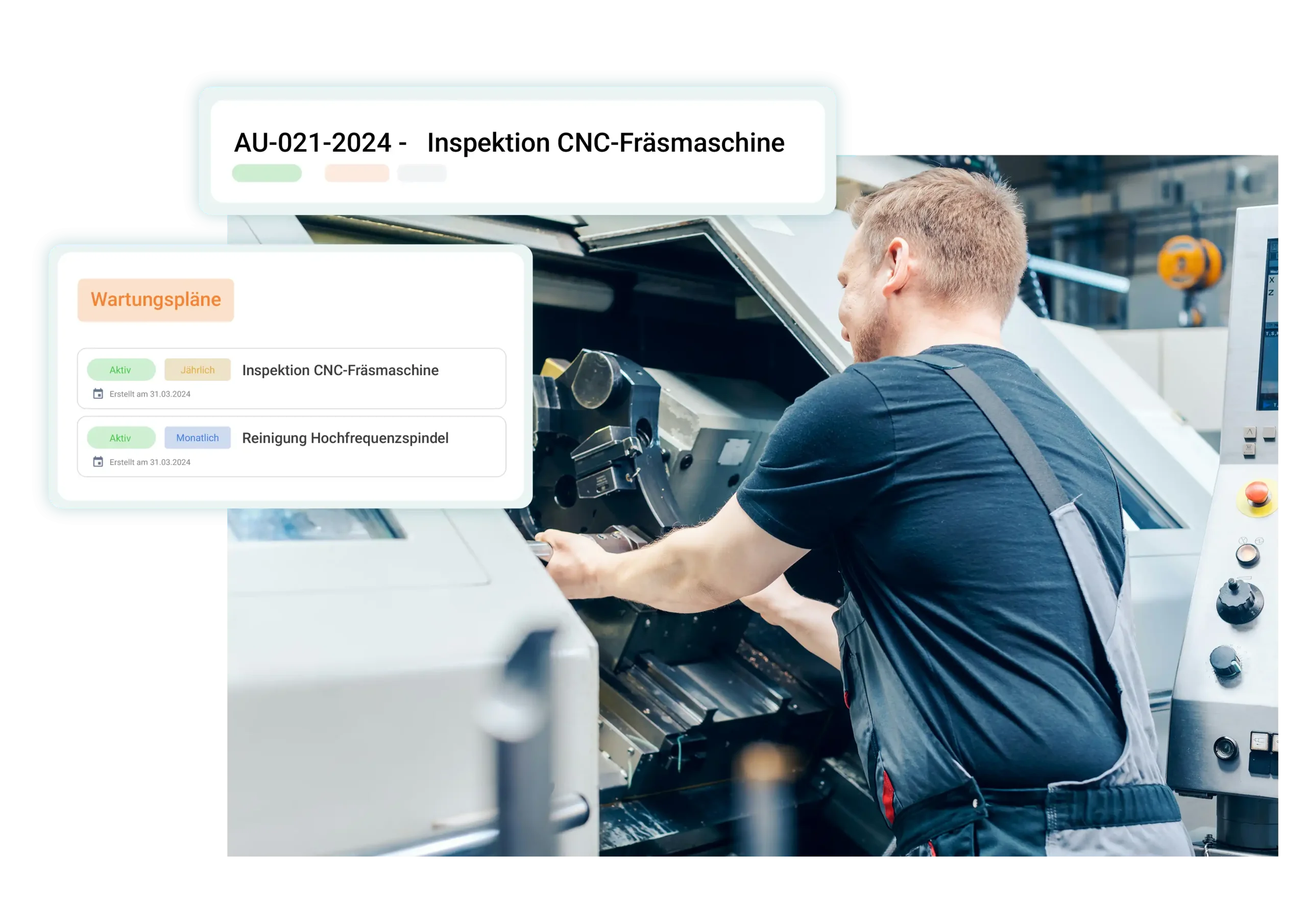

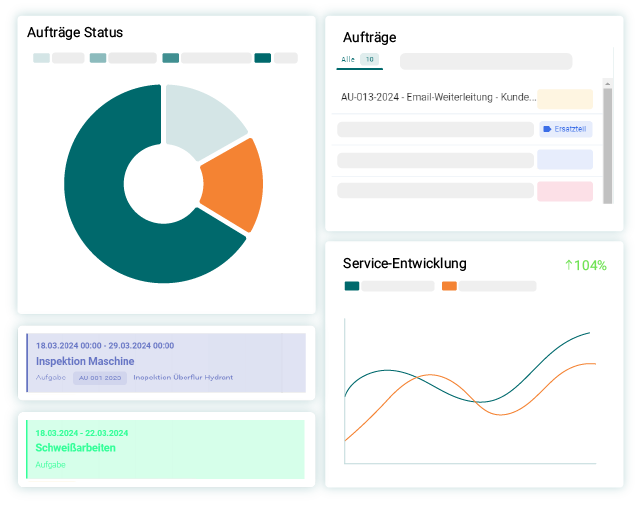

Digital resource planning & service management

Whether milling machine, turning center or grinding system – with SIMPL you coordinate your service technicians exactly where they are needed. You control every step centrally and efficiently, from the receipt of the fault report to the confirmation of the assignment. You benefit from a seamless overview of deadlines, machine status and availability, especially for complex production systems with tight timeframes.

Precisely plan and control service assignments for your machine tools

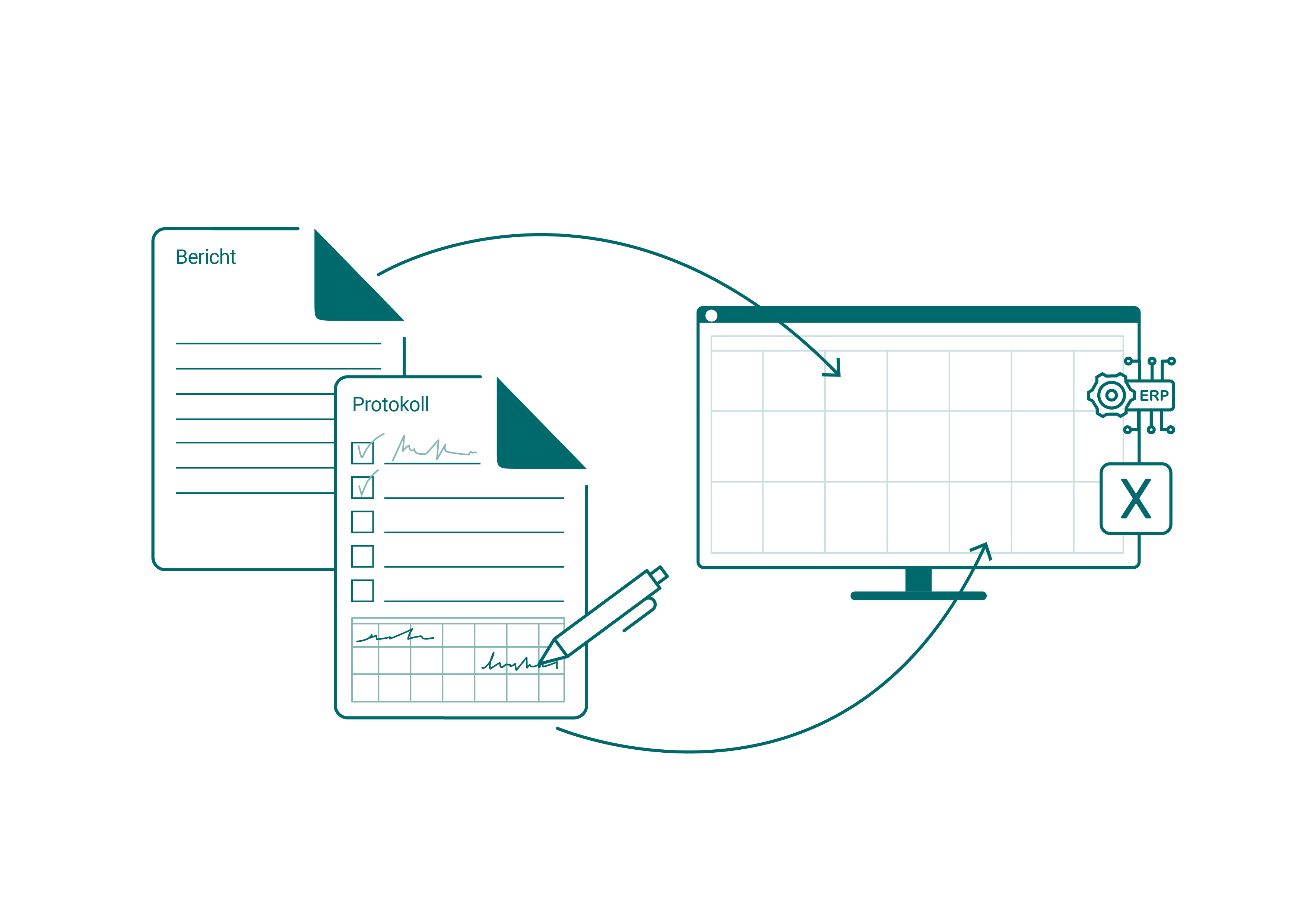

Mobile service reports & digital documentation

Your service teams document maintenance, repairs and machine inspections directly on the system – including photos, measured values, spare parts and customer signatures. Especially for safety-critical components such as spindles, guides or controls, you ensure legally compliant and standard-compliant documentation – without any paper chaos.

Mobile and complete recording of service work on machine tools

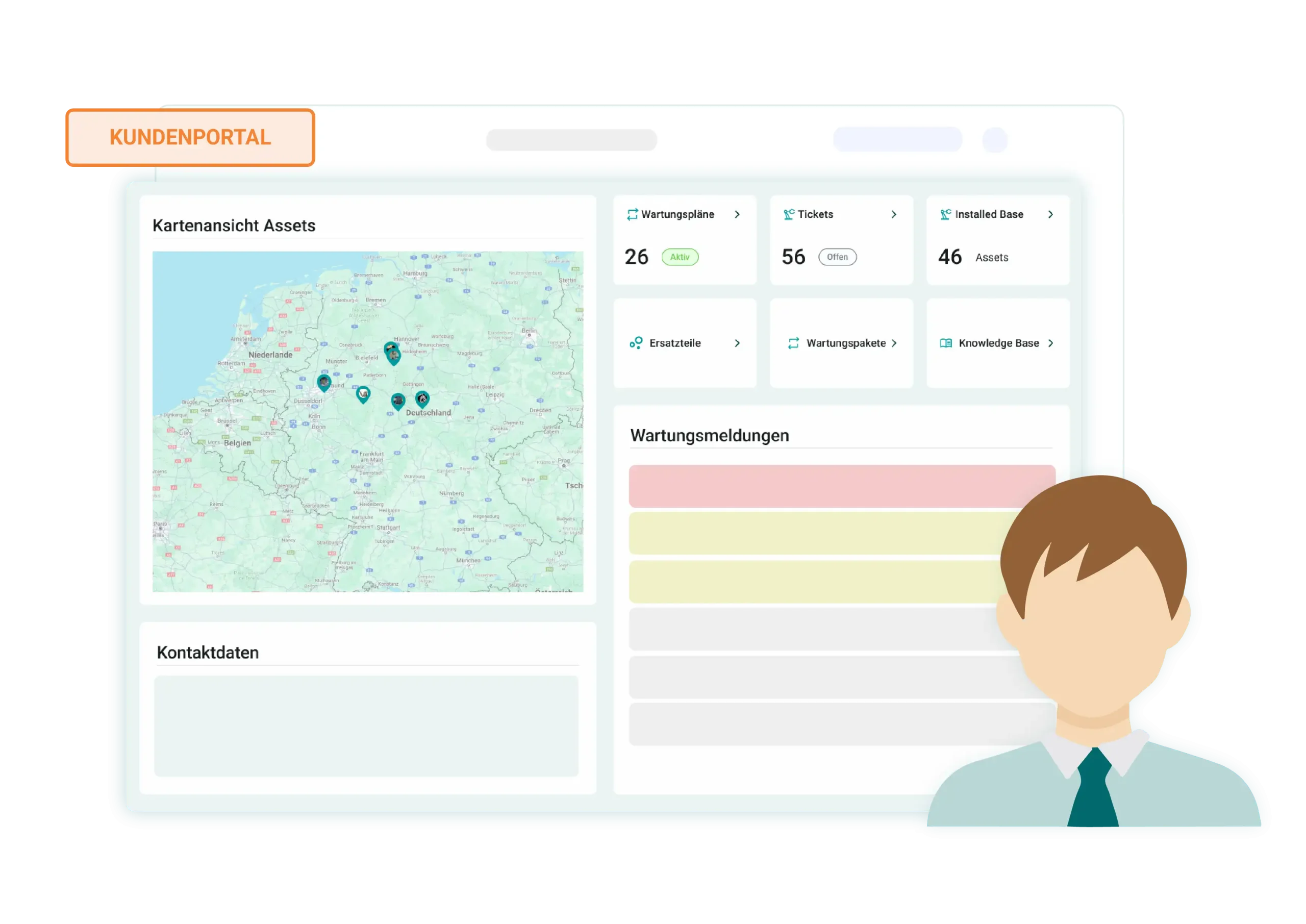

Customer portal & machine history

Offer your customers a digital portal where they can find all relevant information about their machine tools: Maintenance schedules, machine history, inspection logs or spare parts. This reduces queries, speeds up coordination – and creates trust, especially in highly automated manufacturing environments with strictly timed production processes.

Machine data and service reports available to your customers at any time

Less downtime. More turnover in service.

Digitize your service and after-sales processes now and increase the success of your machine tool portfolio.

Individual support from real contacts

We accompany you personally – with support that understands your industry. No call center, no script – just fast, direct help from people who really know SIMPL.

Intuitively developed for use on site

SIMPL also works where speed is of the essence: mobile, offline-capable, without long training periods. Your technicians will get to grips with it straight away – whether using a tablet or smartphone.

Made & hosted in Germany

Our servers are located exclusively in Germany, are ISO 27001-certified and GDPR-compliant. Do your customers demand confidentiality? We provide it as standard.