Safe and digital control of maintenance in the chemical industry

In the chemical industry, maintenance is not just about availability – it’s about safety and compliance. Whether piping systems, pumps, agitators or pressure vessels: maintenance, testing and documentation must be seamless, traceable and legally compliant.

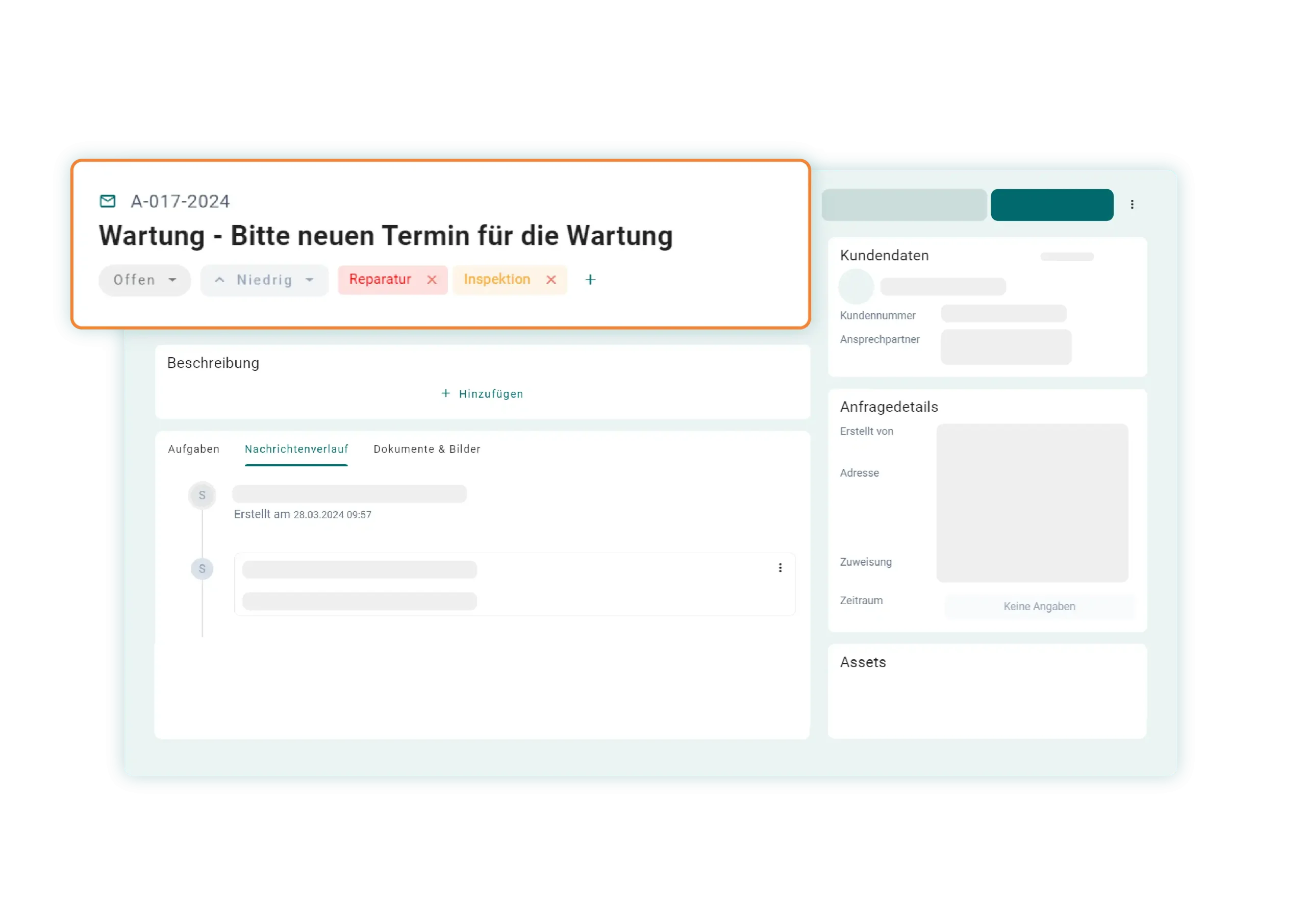

With SIMPL, you can digitalize your maintenance processes end-to-end – from fault reporting and planning to mobile feedback and standard-compliant logging. This allows you to meet regulatory requirements, reduce downtime and relieve your maintenance teams in their day-to-day work.

30

100.000

85

Safety-relevant - but organizationally overloaded?

In the chemical industry, maintenance is more than just a technical necessity – it is a basic requirement for safe operation and regulatory approvals. In practice, however, there is often a lack of resources to record faults in a structured manner, reliably plan maintenance or fully document test protocols.

Paper forms, scattered Excel lists or manual processes cause unnecessary delays, increasing downtime costs and risks during audits. If inspection cycles are overlooked, deadlines are missed or responsibilities are unclear, it is not only availability that is at stake – but also the operating license.

Managing maintenance safely - instead of managing risks

With SIMPL, you can completely digitize your maintenance processes – from reporting and planning to mobile execution and legally compliant documentation. All measures are logged in a traceable manner, systems, test cycles and responsibilities are clearly assigned and can be evaluated at any time.

Whether statutory inspections, recurring maintenance or unplanned faults: You stay in control at all times – and reliably meet requirements from BetrSichV, WHG, IFS or internal compliance specifications. For more safety, less effort – and maintenance that passes inspections before they are announced.

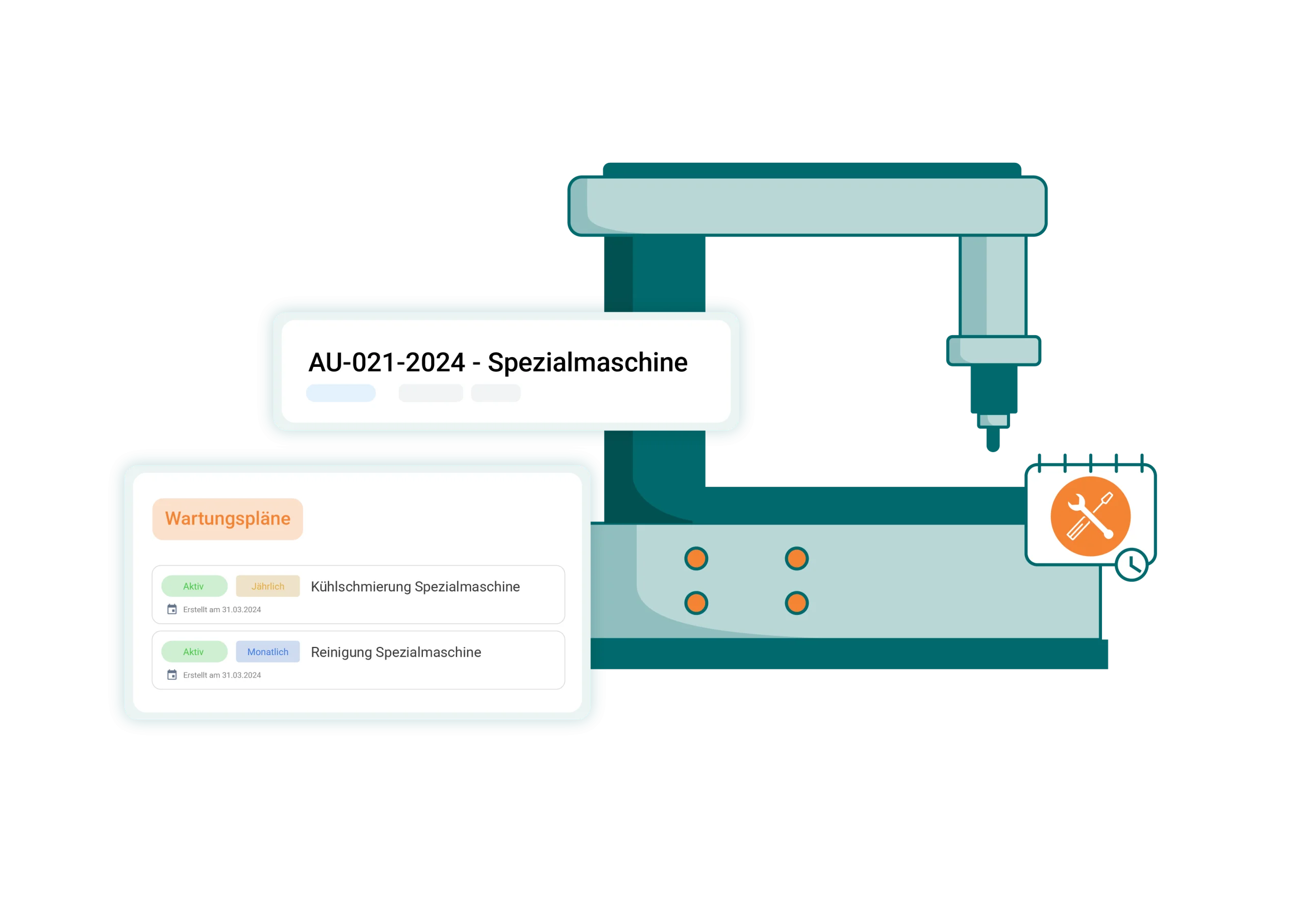

Manage inspection obligations & maintenance plans centrally

With SIMPL, you can manage all maintenance and inspection intervals digitally – including explosion protection, pressure vessel inspections or WHG-relevant systems. You define deadlines, responsibilities and checklists and receive automatic reminders – audit-proof, traceable and exportable at any time.

Safe compliance with legal and operational requirements

Mobile feedback with safety and release documentation

Service technicians document measures on the move – including photos, measured values, material usage, signatures and approval notes. This creates complete, legally compliant reports – directly on the system, without media disruptions and without post-processing in the office.

Mobile recording of maintenance and inspections – with approval on site

Evaluation & audit preparation at the touch of a button

With SIMPL, you can analyze completed measures, open audits, deadline violations or repeat patterns directly in the system. Reports can be exported, shared or used directly for internal audits and official documentation – fast, structured and complete.

Provide reporting, histories and evidence digitally

Security, availability, proof – everything under control digitally

With SIMPL, you can manage your maintenance efficiently, transparently and in compliance with the law – from testing to complete documentation.

Individual support from real contacts

We accompany you personally – with support that understands your industry. No call center, no script – just fast, direct help from people who really know SIMPL.

Intuitively developed for use on site

SIMPL also works where speed is of the essence: mobile, offline-capable, without long training periods. Your technicians will get to grips with it straight away – whether using a tablet or smartphone.

Made & hosted in Germany

Our servers are located exclusively in Germany, are ISO 27001-certified and GDPR-compliant. Do your customers demand confidentiality? We provide it as standard.